Nadcap Approved

Kepston are NADCAP Approved for Brazing and Heat Treatment. This approval places Kepston amongst the elite in the in the Aerospace Supply Chain. NADCAP Approval of the Brazing and Heat Treatment Special Processes has further improved our already solid industry proven Quality Systems and Processes to allow them to meet the high demands required for Brazing and Heat Treating critical Aerospace Components. The NADCAP Special Process Approval for Brazing and Heat Treatment allows companies within the Aerospace supply chain to benefit from Knowledge, commitment, quality and service that Kepston have to offer. The NADCAP Approval for Brazing and Heat Treatment covers all our Vacuum Processes and also our Continuous Hydrogen Brazing.

Our Processes

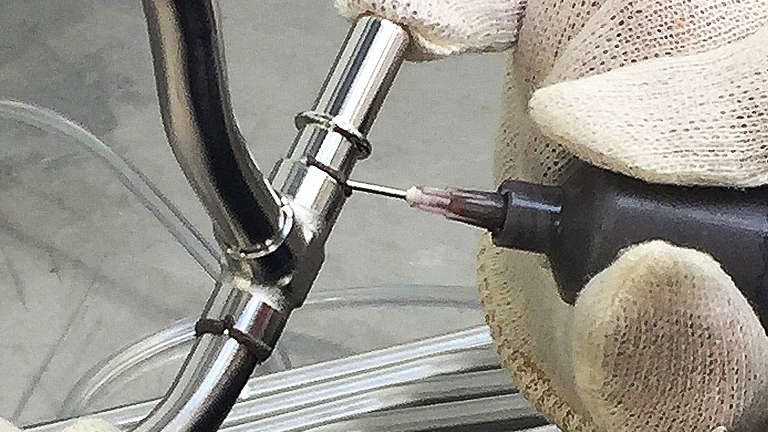

Vacuum & Continuous Furnace Brazing

Furnace Brazing is still one of the least appreciated manufacturing techniques with many engineers being unaware of its existence or its advantages. It permits the brazing of multi-jointed components without the use of flux.

Vacuum & Continuous Bright Annealing

Carried out in a controlled furnace atmosphere to ensure a clean & scale free surface. Ideal when secondary operations are required such as forming or bending & can be electroplated.

Magnetic Annealing

Carried out under a hydrogen furnace atmosphere. Extended soak times & controlled cooling rates ensure optimum soft magnetic properties.

Vacuum, Continuous & Batch Heat Treatment

Heat Treatment has long been recognised as one of the essential weapons in the metallurgist's armoury and is capable of radically changing the structure of metal.